ISO 9001 Certified Vithy: Leading Supplier of Continuous In-Line Self-Cleaning Scraper Filters

SHANGHAI, JINSHAN, CHINA, January 23, 2026 /EINPresswire.com/ -- Vithy, an ISO 9001 certified manufacturer, continues to make strides toward automating industrial filtration systems and is at the forefront of developing liquid-solid separation technologies. As a Leading Continuous In-Line Self-cleaning Scraper Filter Supplier, the organization specializes in mechanical filtration solutions that operate without manual filter media replacement or process interruption. The continuous in-line self-cleaning scraper filter functions by utilizing a motor-driven scraping system to remove debris from the internal or external surface of a permanent filter element. This design addresses the operational challenges associated with high-viscosity fluids and high-solid loadings, maintaining a constant flow rate and protecting downstream industrial infrastructure from particulate contamination.

Global Industrial Filtration: Sector Trends and Future Projections

The global industrial filtration market is currently experiencing an unprecedented transition, marked by automation implementation and environmental sustainability concerns. Industry analysis indicates that self-cleaning technology adoption has seen dramatic gains as manufacturers look for alternatives to labor intensive batch filtration methods; this trend can partly be explained by Industry 4.0 principles which emphasize real time monitoring and autonomous operation with real time operation; both principles aim at minimizing human error while simultaneously optimizing plant uptime.

Environmental regulations concerning wastewater discharge and solid waste management have also altered industry priorities. Traditional filtration consumables, like disposable bags and cartridges, contribute significantly to landfill waste production as they require replacement cycles; additionally they expose workers to chemicals during replacement cycles that increase chemical exposure risk. As a result, there has been an international shift towards permanent media filtration systems. Furthermore, with rising raw material costs necessitating recovery of costly catalysts and process fluids at a financial cost - further solidifying automated scraper filters' role. With water scarcity becoming an issue worldwide manufacturing hubs face increasing challenges maintaining efficient cooling loops through advanced filtration as an operational preference or regulatory mandate.

In the current economic climate, the scarcity of skilled labor in specialized manufacturing zones has further accelerated the transition to automated systems. Filtration units that require minimal intervention allow facilities to reallocate personnel to more complex tasks. This shift is particularly evident in the chemical, pharmaceutical, and energy sectors, where the requirement for hermetically sealed systems—to protect both the environment and the operator—is now a standard industry benchmark.

Quality Management and the Strategic Role of ISO 9001 Certification

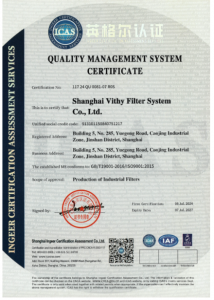

Vithy Filtration's operations are guided by ISO 9001, an internationally acclaimed Quality Management Systems (QMS) standard. For manufacturers of high-pressure filtration equipment, certification under this framework represents a commitment to consistency, safety and regulatory compliance across their entire production lifecycle; from procurement of raw materials and precision engineering through rigorous pressure testing of filter housings.

ISO 9001 standards have become an indispensable resource in the filtration industry, guaranteeing every unit produced conforms to strict tolerances and material certifications - something especially crucial when equipment is installed in volatile environments like petrochemical refineries or high-temperature chemical processing plants. Certification involves regular internal and external audits to verify that processes are documented, transparent, and subject to continuous improvement; additionally this quality framework facilitates traceability by tracking components and materials used in each scraper filter construction project.

By adhering to international standards, an organization ensures its products meet the technical specifications of global markets. ISO 9001's "Plan-Do-Check-Act" (PDCA) cycle allows identification of any design or manufacturing risks before equipment reaches sites for delivery; industrial end-users use certification as proof that their filtration systems will perform according to specified technical parameters for extended operational lifespans.

Core Technical Capabilities and Industrial Application Scenarios

The technical expertise within the organization is centered on solving complex solid-liquid separation challenges through a diverse portfolio of automated products. The primary advantage of the Vithy system lies in the precision of its scraping technology, which maintains the integrity of the filter media while effectively clearing debris. This capability is supported by an in-house laboratory where fluid samples are analyzed to determine the optimal filtration fineness and material compatibility for each specific industrial use case.

Core Technical Capabilities

High-Viscosity Handling:Vithy's scraper filters are specifically designed to handle highly viscous process fluids like resins, polymers and thick food slurries with ease. Their mechanical scraping mechanism guarantees consistent flow rates while avoiding blinding even when dealing with materials which traditional systems cannot manage.

Specialized Scraper Technologies: Vithy offers customized solutions, such as the VAS-I (Internal Scraper) and VAS-O (External Scraper) models of its Specialized Scraper Technologies, featuring high performance scrapers designed to effectively clear debris off filter surfaces without disrupting production.

Precision Filter Elements: The equipment utilizes Wedge Mesh (Wedge Wire) or Perforated Mesh filter elements (typically 25um to 5000um in size) designed to withstand high differential pressures and heavy solid loads.

Intelligent Automation: Integrating with a PLC control system, our filters offer automated cleaning cycles triggered by Time Intervals or Differential Pressure for 24/7 continuous operation.

The application of the Continuous In-Line Self-cleaning Scraper Filter spans multiple high-demand sectors:

Chemical and Petrochemical Processing: Used for the filtration of resins, monomers, polymers, and adhesives. The systems are designed to handle the high viscosities and temperatures often found in chemical synthesis.

Food and Beverage Production: Applied in the filtration of liquid chocolate, edible oils, and corn syrup. The closed-loop design prevents contamination and ensures the purity of the final consumer product.

Pulp and Paper Industry: Essential for the filtration of paper coatings and additives, preventing the clogging of spray nozzles and ensuring a smooth finish on the paper surface.

Environmental and Water Utility: Employed in the pre-filtration of intake water and the treatment of industrial effluent to meet discharge standards.

The organization’s client portfolio includes established global entities and state-owned enterprises. These references indicate a capacity to meet the rigorous safety and technical documentation standards required by large-scale multinational corporations. In addition to the scraper filter series, the organization provides a range of auxiliary equipment, including leaf filters, candle filters, and advanced bag filters, providing a comprehensive suite of tools for various flow requirements and particulate types.

Conclusion

Industrial filtration technology remains an integral component in achieving manufacturing efficiency and environmental responsibility worldwide. Through implementation of ISO 9001 quality standards and development of automated systems such as Vithy's automated liquid-solid separation systems, we continue to meet the evolving needs of liquid-solid separation market. Continuous self-cleaning filtration represents a major breakthrough for reducing operational waste while protecting industrial processes worldwide - as industries automate and modernize, such systems will remain essential components of global infrastructure.

For further information regarding technical specifications and the full range of filtration products, please visit the official website: https://www.vithyfiltration.com/

Global Industrial Filtration: Sector Trends and Future Projections

The global industrial filtration market is currently experiencing an unprecedented transition, marked by automation implementation and environmental sustainability concerns. Industry analysis indicates that self-cleaning technology adoption has seen dramatic gains as manufacturers look for alternatives to labor intensive batch filtration methods; this trend can partly be explained by Industry 4.0 principles which emphasize real time monitoring and autonomous operation with real time operation; both principles aim at minimizing human error while simultaneously optimizing plant uptime.

Environmental regulations concerning wastewater discharge and solid waste management have also altered industry priorities. Traditional filtration consumables, like disposable bags and cartridges, contribute significantly to landfill waste production as they require replacement cycles; additionally they expose workers to chemicals during replacement cycles that increase chemical exposure risk. As a result, there has been an international shift towards permanent media filtration systems. Furthermore, with rising raw material costs necessitating recovery of costly catalysts and process fluids at a financial cost - further solidifying automated scraper filters' role. With water scarcity becoming an issue worldwide manufacturing hubs face increasing challenges maintaining efficient cooling loops through advanced filtration as an operational preference or regulatory mandate.

In the current economic climate, the scarcity of skilled labor in specialized manufacturing zones has further accelerated the transition to automated systems. Filtration units that require minimal intervention allow facilities to reallocate personnel to more complex tasks. This shift is particularly evident in the chemical, pharmaceutical, and energy sectors, where the requirement for hermetically sealed systems—to protect both the environment and the operator—is now a standard industry benchmark.

Quality Management and the Strategic Role of ISO 9001 Certification

Vithy Filtration's operations are guided by ISO 9001, an internationally acclaimed Quality Management Systems (QMS) standard. For manufacturers of high-pressure filtration equipment, certification under this framework represents a commitment to consistency, safety and regulatory compliance across their entire production lifecycle; from procurement of raw materials and precision engineering through rigorous pressure testing of filter housings.

ISO 9001 standards have become an indispensable resource in the filtration industry, guaranteeing every unit produced conforms to strict tolerances and material certifications - something especially crucial when equipment is installed in volatile environments like petrochemical refineries or high-temperature chemical processing plants. Certification involves regular internal and external audits to verify that processes are documented, transparent, and subject to continuous improvement; additionally this quality framework facilitates traceability by tracking components and materials used in each scraper filter construction project.

By adhering to international standards, an organization ensures its products meet the technical specifications of global markets. ISO 9001's "Plan-Do-Check-Act" (PDCA) cycle allows identification of any design or manufacturing risks before equipment reaches sites for delivery; industrial end-users use certification as proof that their filtration systems will perform according to specified technical parameters for extended operational lifespans.

Core Technical Capabilities and Industrial Application Scenarios

The technical expertise within the organization is centered on solving complex solid-liquid separation challenges through a diverse portfolio of automated products. The primary advantage of the Vithy system lies in the precision of its scraping technology, which maintains the integrity of the filter media while effectively clearing debris. This capability is supported by an in-house laboratory where fluid samples are analyzed to determine the optimal filtration fineness and material compatibility for each specific industrial use case.

Core Technical Capabilities

High-Viscosity Handling:Vithy's scraper filters are specifically designed to handle highly viscous process fluids like resins, polymers and thick food slurries with ease. Their mechanical scraping mechanism guarantees consistent flow rates while avoiding blinding even when dealing with materials which traditional systems cannot manage.

Specialized Scraper Technologies: Vithy offers customized solutions, such as the VAS-I (Internal Scraper) and VAS-O (External Scraper) models of its Specialized Scraper Technologies, featuring high performance scrapers designed to effectively clear debris off filter surfaces without disrupting production.

Precision Filter Elements: The equipment utilizes Wedge Mesh (Wedge Wire) or Perforated Mesh filter elements (typically 25um to 5000um in size) designed to withstand high differential pressures and heavy solid loads.

Intelligent Automation: Integrating with a PLC control system, our filters offer automated cleaning cycles triggered by Time Intervals or Differential Pressure for 24/7 continuous operation.

The application of the Continuous In-Line Self-cleaning Scraper Filter spans multiple high-demand sectors:

Chemical and Petrochemical Processing: Used for the filtration of resins, monomers, polymers, and adhesives. The systems are designed to handle the high viscosities and temperatures often found in chemical synthesis.

Food and Beverage Production: Applied in the filtration of liquid chocolate, edible oils, and corn syrup. The closed-loop design prevents contamination and ensures the purity of the final consumer product.

Pulp and Paper Industry: Essential for the filtration of paper coatings and additives, preventing the clogging of spray nozzles and ensuring a smooth finish on the paper surface.

Environmental and Water Utility: Employed in the pre-filtration of intake water and the treatment of industrial effluent to meet discharge standards.

The organization’s client portfolio includes established global entities and state-owned enterprises. These references indicate a capacity to meet the rigorous safety and technical documentation standards required by large-scale multinational corporations. In addition to the scraper filter series, the organization provides a range of auxiliary equipment, including leaf filters, candle filters, and advanced bag filters, providing a comprehensive suite of tools for various flow requirements and particulate types.

Conclusion

Industrial filtration technology remains an integral component in achieving manufacturing efficiency and environmental responsibility worldwide. Through implementation of ISO 9001 quality standards and development of automated systems such as Vithy's automated liquid-solid separation systems, we continue to meet the evolving needs of liquid-solid separation market. Continuous self-cleaning filtration represents a major breakthrough for reducing operational waste while protecting industrial processes worldwide - as industries automate and modernize, such systems will remain essential components of global infrastructure.

For further information regarding technical specifications and the full range of filtration products, please visit the official website: https://www.vithyfiltration.com/

Shanghai Vithy Filter System Co., Ltd.

Shanghai Vithy Filter System Co., Ltd.

+86 15821373166

export02@vithyfilter.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.